The design and construction of the medical clean door workshop, the manufacturing and installation of equipment and facilities in the workshop, the quality of raw and auxiliary materials for production, packaging materials, and the poor implementation of the control procedure of human purification and physical purification facilities will affect the product quality.

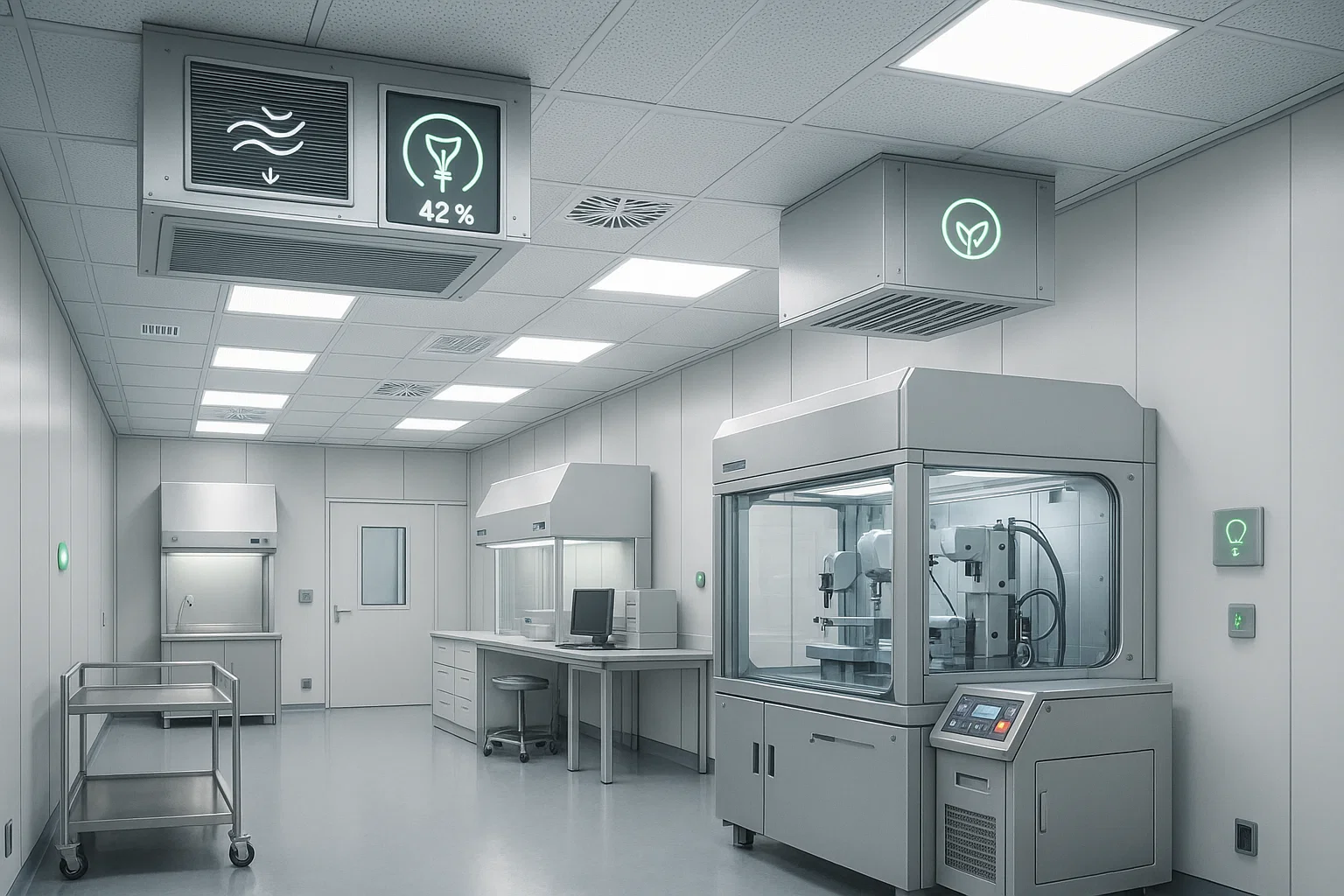

Medical clean door refers to a room with a special design, which can eliminate the pollutants such as particulates, harmful air and bacteria in the air within a certain space range, and control the indoor temperature, cleanliness, indoor pressure, air velocity and air distribution, noise, vibration, lighting and static electricity within a certain demand range. That is to say, no matter how the external air conditions change, the indoor can maintain the original set requirements of cleanliness, temperature, humidity and pressure.

The main function of the medical clean door is to control the cleanliness, temperature and humidity of the air the product contacts so that the product can be produced and manufactured in a good environmental space. According to international practice, the level of dust-free purification is mainly determined by the number of particles whose diameter is greater than the division standard per cubic meter of air. In other words, the so-called dust-free is not without a little dust but is controlled in a tiny unit.

English

English русский

русский Español

Español