Cleanroom automatic sliding doors are designed with several features and technologies to minimize contamination risks when opening and closing. Here are the key factors that contribute to maintaining a clean environment:

1. Seamless, Tight Sealing

Door Seals: Automatic sliding doors are equipped with high-quality seals (e.g., silicone, rubber, or foam) around the edges to ensure that no air or particles can leak through when the door is closed. These seals prevent contaminants from entering the cleanroom and help maintain pressure differentials.

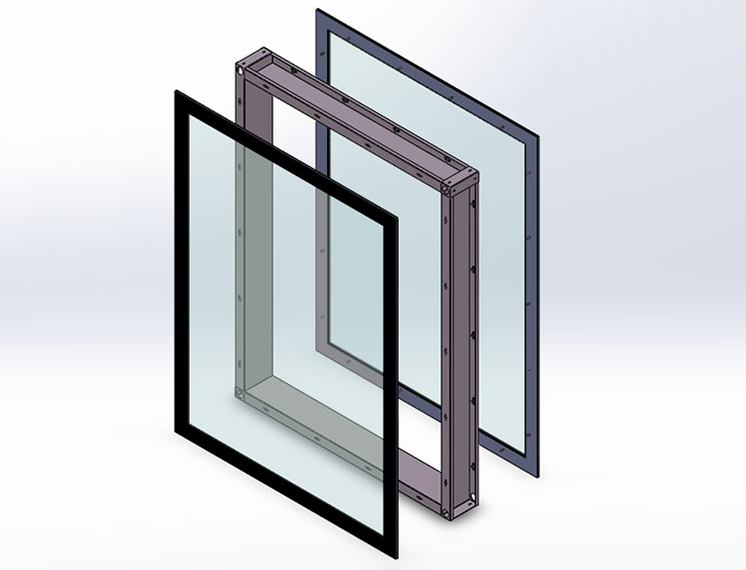

Minimal Gaps: The design of the door frames and panels ensures that they fit tightly when closed, minimizing gaps where dust or particles could enter.

2. Smooth, Continuous Movement

Controlled Opening and Closing Speeds: The doors are designed to open and close smoothly and at a controlled speed, reducing air turbulence that could stir up particles. Rapid movements can create air currents that disturb particles settled on surfaces, so a slower, controlled motion ensures less disruption of the cleanroom environment.

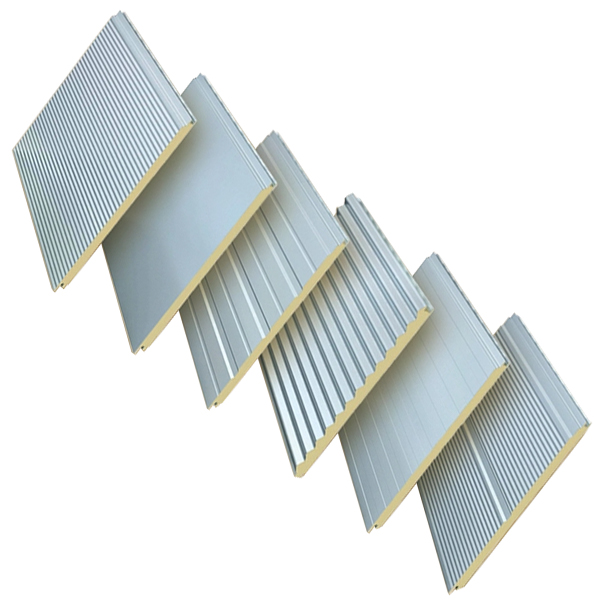

Smooth Surface: The surface of the doors is smooth and non-porous, which prevents dust or contaminants from accumulating and makes cleaning easier.

3. Positive and Negative Pressure Control

Airlock Functionality: In many cleanroom designs, automatic sliding doors are used in conjunction with airlocks or vestibules to control the pressure differential. By maintaining either a positive or negative air pressure relative to the external environment, these doors ensure that air flow is directed into or out of the cleanroom in a controlled manner, preventing outside contaminants from entering.

Pressure Sensors: Automatic sliding doors are often linked to air pressure control systems to automatically adjust the door’s operation according to the cleanroom’s pressure requirements.

4. Sensor Integration for Safety and Efficiency

Motion Sensors: To minimize the amount of time the door remains open, motion sensors (e.g., infrared, radar, or ultrasonic) detect approaching personnel or equipment and trigger the door to open and close quickly but safely. The sensors ensure that doors do not remain open longer than necessary, reducing the risk of contamination from the outside environment.

Barrier-Free Sensors: These sensors are often designed to minimize disturbances to the airflow or cause unnecessary opening/closing cycles. This helps keep the cleanroom environment stable and prevents contamination from external sources.

5. HEPA/ULPA Filter Integration

Air Filtration: In some cases, automatic sliding doors may be equipped with HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters within the door frame to further clean the air entering or leaving the cleanroom when the door opens. This filtration system traps particles and reduces the risk of contamination when the door is in operation.

6. Low Static Build-Up

Anti-Static Coatings: Some automatic sliding doors come with anti-static properties or coatings, which help reduce the attraction of dust and particles to the door surface. By minimizing static build-up, they help prevent the accumulation of airborne contaminants.

7. Cleanroom-Compatible Materials

Non-Porous Materials: The door materials—typically stainless steel, anodized aluminum, or high-quality plastics—are resistant to contamination because they are non-porous and do not harbor dirt or dust. This helps reduce the risk of cross-contamination.

Corrosion-Resistant Finishes: These finishes are used to ensure the door surfaces do not degrade over time, which could lead to particle shedding or contamination.

8. Remote Control and Automation

Automated Control Systems: The automatic systems that control the opening and closing of doors can be linked to the cleanroom’s central control system to ensure they operate efficiently and minimize contamination. For example, automated systems can be programmed to only open when necessary, ensuring minimal disturbance to the environment.

Touchless Operation: Many automatic sliding doors can be activated without physical contact, reducing the risk of introducing contaminants from door handles or manual operation.

9. Maintenance and Cleaning Protocols

Easy Maintenance: Automatic sliding doors in cleanrooms are designed for easy cleaning and maintenance. Because cleanroom environments require strict hygiene, regular cleaning of the door seals, tracks, and surfaces is essential to prevent the accumulation of dust or particles that might compromise the cleanroom's standards.

Self-Cleaning Features: Some doors are designed with self-cleaning features, such as dust-resistant coatings or air jets, to minimize the need for frequent manual cleaning.

English

English русский

русский Español

Español