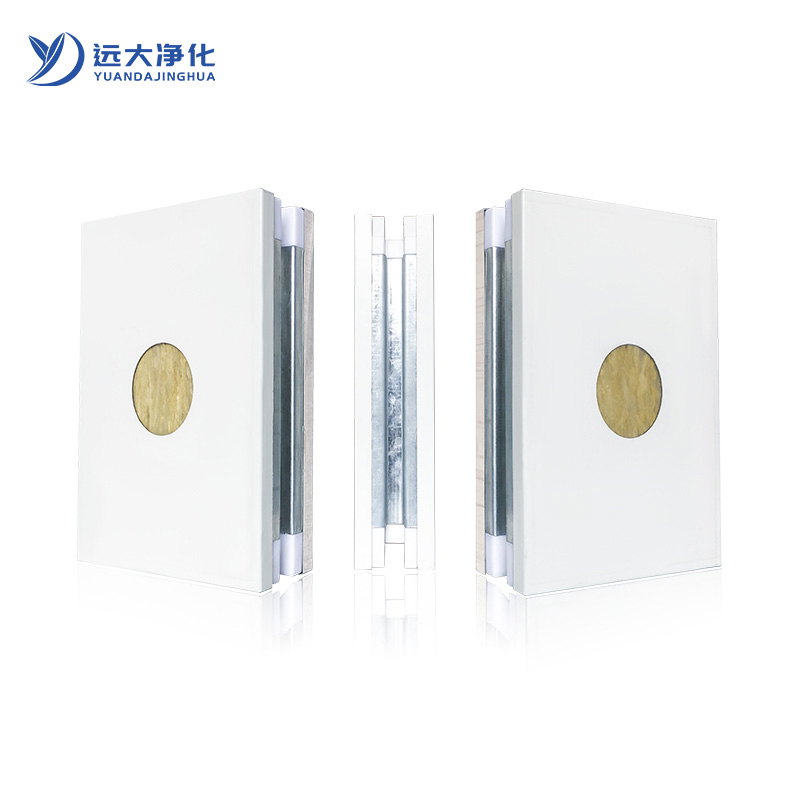

The core material in PCGI (Pre-Coated Galvanized Iron) sandwich panels plays a critical role in determining both the structural strength and thermal properties of the panel. Here's how the core material influences these key aspects:

Structural Strength

Load-Bearing Capacity: The core material contributes significantly to the panel's overall stiffness and load-bearing capabilities. It supports the outer layers (galvanized iron sheets), helping them withstand compression, tension, and shear forces. The core effectively distributes the loads across the panel, making it suitable for structural applications.

Impact Resistance: The choice of core material can enhance the panel's resistance to impact and mechanical damage. Some cores, like polyurethane foam, can absorb energy from impacts, providing additional protection.

Core Types and Their Impact:

Polyurethane Foam (PU): Offers good stiffness and strength while being lightweight, making it suitable for applications where weight reduction is important.

Expanded Polystyrene (EPS): Provides decent structural support but is less stiff compared to other cores, making it better suited for non-load-bearing applications.

Mineral Wool: Known for its high density and fire-resistant properties, mineral wool cores can increase the panel's structural integrity, especially in fire-rated applications.

Thermal Properties

Insulation Performance: The core material significantly influences the thermal insulation properties of the panel. High-quality insulating materials, such as polyurethane foam, have low thermal conductivity, which helps reduce heat transfer and improves energy efficiency in buildings.

Thermal Resistance (R-Value): Different core materials offer varying levels of thermal resistance. For example, polyurethane foam generally provides a higher R-value compared to EPS, meaning better insulation performance for the same thickness.

Minimizing Thermal Bridging: The core acts as a thermal break between the outer layers, reducing the potential for thermal bridging, which occurs when heat flows through more conductive materials (like metal).

Acoustic Insulation

Sound Dampening: Some core materials, such as mineral wool, can also enhance the sound insulation properties of the panels by absorbing sound waves. This makes them suitable for applications where noise reduction is important.

Fire Resistance

Fire Performance of the Core Material: The fire resistance of the sandwich panel is largely determined by the properties of the core. For example, mineral wool is non-combustible and provides superior fire resistance, while polyurethane foam may require fire-retardant treatments to meet safety standards.

English

English русский

русский Español

Español