The sealing performance of cleanroom doors is a crucial factor in ensuring the quality of the cleanroom environment. The following is a detailed explanation of how to guarantee the sealing performance of cleanroom doors:

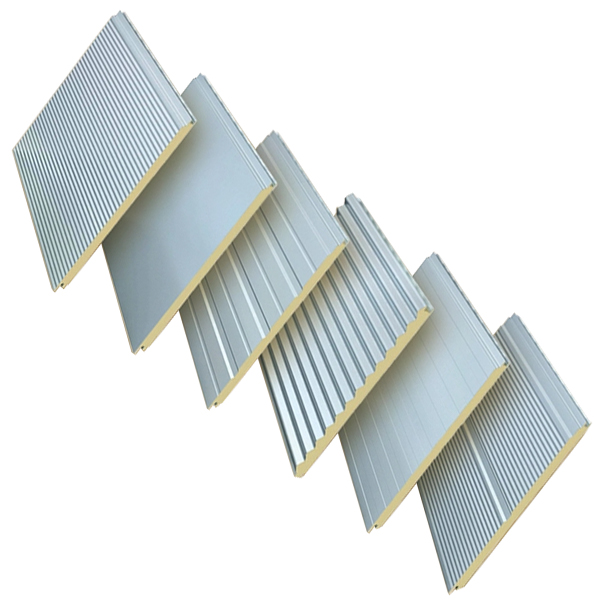

Selection of Sealing Materials: Cleanroom doors typically use high-quality sealing strip materials that exhibit good elasticity and durability, capable of adapting to changes in different temperature and humidity conditions. The sealing strip materials should closely fit the door frame, ensuring no air leakage when the door is closed.

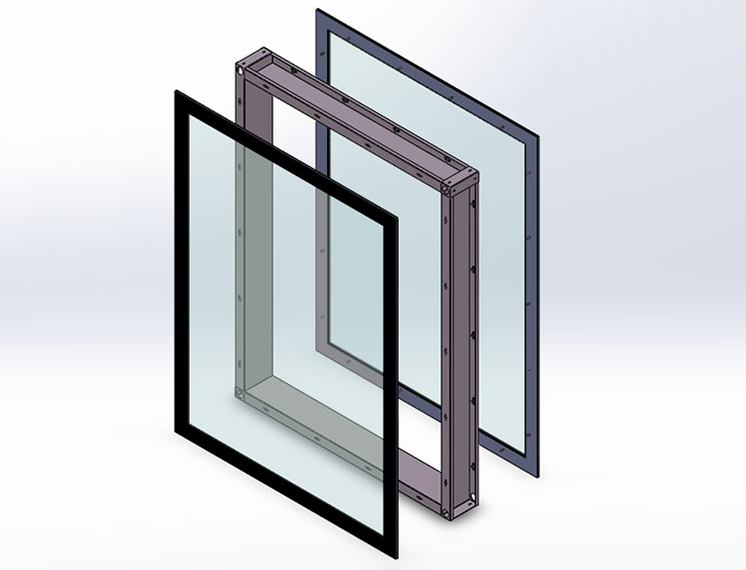

Double Sealing Design: Some cleanroom door designs incorporate a double-sealing structure, with two sealing strips positioned between the door leaf and the door frame. This design further reduces the likelihood of air leakage and enhances the door's sealing performance.

Installation Precision: The installation of cleanroom doors requires extremely high precision to ensure that the gap between the door and the frame is uniform and minimal. Any excessive gaps could lead to air leakage, compromising the cleanliness of the cleanroom.

Pressure Testing: After installation, cleanroom doors need to undergo pressure testing to verify their sealing performance. These tests ensure that the doors can effectively prevent the exchange of air between the interior and exterior under normal usage conditions.

Inspection and Maintenance of Sealing Strips: The sealing performance of cleanroom doors requires regular inspection and maintenance to ensure continuous effectiveness. This includes checking if the sealing strips are intact, if there is any wear or aging, and timely replacement of damaged sealing strips.

Compatibility of Door Leaf and Frame: The compatibility between the door leaf and the door frame is crucial for sealing performance. Proper compatibility reduces friction between the door leaf and frame, thereby enhancing the door’s sealing performance.

Consideration of Usage Environment: When selecting sealing materials and designing the sealing structure, it is necessary to consider the specific usage environment of the cleanroom. For instance, if there are special chemical gases or particles in the cleanroom, materials resistant to these factors should be chosen.

Compliance with Standards and Certifications: The sealing performance of cleanroom doors should comply with relevant national or industry standards. Necessary certifications and tests can ensure that the door’s sealing performance meets the required specifications.

The sealing performance of cleanroom doors is ensured through a combination of selecting appropriate sealing materials, employing double sealing designs, ensuring installation precision, conducting pressure tests, regular inspections and maintenance, and considering the usage environment. These measures work together to guarantee the sealing performance of cleanroom doors, thereby ensuring the cleanliness and stability of the cleanroom environment.

English

English русский

русский Español

Español