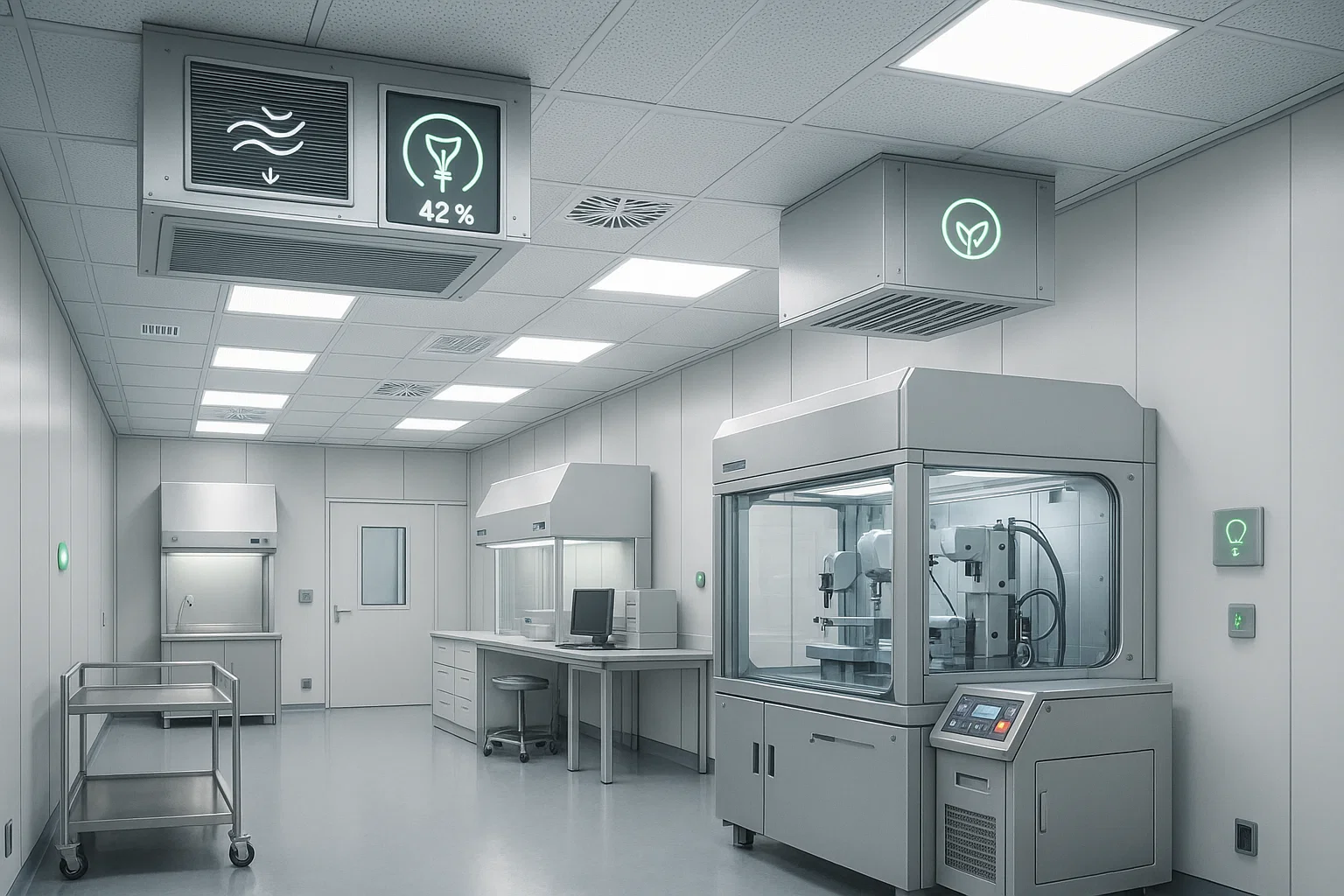

Clean room windows play a vital role in maintaining the integrity of controlled environments, where even the smallest contaminants can jeopardize product quality and safety. These specialized windows are utilized in several industries, each with unique requirements that necessitate stringent cleanliness standards. Let’s explore the key sectors where clean room windows are most commonly employed.

Pharmaceuticals

The pharmaceutical industry is perhaps the most critical user of clean room windows. In facilities where medications and vaccines are manufactured, maintaining a sterile environment is paramount. Clean room windows allow for visibility into production areas while preventing contaminants from entering. These windows are often made from materials that resist chemical corrosion and are easy to clean, ensuring compliance with rigorous industry regulations.

Biotechnology

Biotechnology labs, where biological materials are researched and developed, rely heavily on clean room windows. These environments require precise control over airborne particles and microbial contamination. Clean room windows facilitate observation of laboratory processes without compromising the sterile conditions essential for experiments and product development.

Electronics Manufacturing

In the electronics industry, clean room windows are crucial for producing sensitive components like semiconductors and circuit boards. Even minute dust particles can affect performance, making cleanliness vital. Clean room windows enable technicians to monitor manufacturing processes while ensuring that clean room standards are upheld, thus safeguarding the quality of electronic products.

Aerospace

The aerospace sector also benefits from clean room windows, especially during the manufacturing of components for aircraft and spacecraft. These environments demand high levels of cleanliness to prevent defects in precision components that could jeopardize safety. Clean room windows allow for visual inspections without exposing the environment to contaminants.

Food and Beverage

While less commonly associated with clean rooms, the food and beverage industry has recognized the importance of maintaining cleanliness in certain production areas. Clean room windows help monitor operations in environments where hygiene is crucial, such as in the processing of ready-to-eat foods and pharmaceuticals.

Medical Device Manufacturing

Clean room windows are essential in the production of medical devices, where sterility and precision are non-negotiable. These windows enable manufacturers to maintain a clear view of production lines while ensuring that the environment remains uncontaminated, thus protecting both product integrity and patient safety.

Clean room windows are indispensable in various industries where contamination control is essential. From pharmaceuticals and biotechnology to electronics manufacturing and aerospace, these specialized windows facilitate monitoring and inspection while ensuring compliance with strict cleanliness standards. As industries continue to evolve, the role of clean room windows will remain critical in supporting innovation and safety in controlled environments.

English

English русский

русский Español

Español