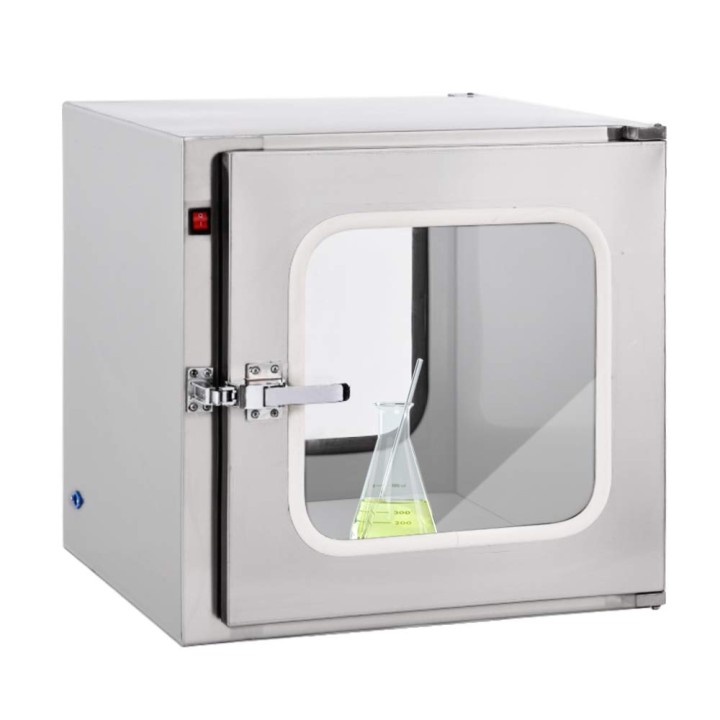

In highly regulated industries like pharmaceuticals, biotechnology, and healthcare, maintaining a sterile environment is paramount. Pass-through boxes, which facilitate the safe transfer of materials between rooms with different cleanliness levels, play a vital role in this process. A key feature of many pass-through boxes is the use of stainless steel as the primary construction material. This article explores the numerous benefits of stainless steel for pass-through boxes in sterile environments, highlighting why it is the material of choice.

1. Corrosion Resistance

One of the standout benefits of stainless steel is its resistance to corrosion. Sterile environments, especially in pharmaceutical and biotechnology settings, often require rigorous cleaning procedures that involve strong disinfectants and chemicals. Over time, these chemicals can cause corrosion in many materials. Stainless steel, however, has a natural resistance to rust and corrosion due to the presence of chromium, which forms a protective oxide layer. This ensures that the pass-through box remains intact, durable, and free from contaminants that could compromise sterile conditions.

2. Easy to Clean and Sterilize

Maintaining cleanliness in a sterile environment is crucial, and stainless steel is one of the easiest materials to clean. Its non-porous, smooth surface allows for quick and thorough cleaning, preventing the buildup of dirt, bacteria, or chemical residues. Moreover, stainless steel can withstand exposure to various sterilization methods, including chemical disinfectants, steam, and heat-based processes like autoclaving. The ease of sterilization helps ensure that pass-through boxes remain free from microbial contamination, maintaining the sterility of the environment.

3. Non-Reactive and Chemically Inert

In sterile environments, it is critical that materials do not react with the substances they come into contact with. Stainless steel is chemically inert, meaning it does not interact with most chemicals, drugs, or biological substances. This characteristic is particularly important in the pharmaceutical industry, where any unintended reactions could compromise the purity and safety of the products being handled. The non-reactive nature of stainless steel makes it a safe material for use in pass-through boxes, as it ensures that items being transferred remain uncontaminated.

4. Durability and Strength

Stainless steel is renowned for its strength and durability. In environments where pass-through boxes are frequently used, exposed to constant handling, or moved, the material must be able to withstand wear and tear. Stainless steel can endure mechanical stress without deforming, denting, or cracking, ensuring that the pass-through box remains fully operational. This durability is crucial for maintaining airtight seals and the interlocking door mechanisms that are essential for preventing cross-contamination between cleanrooms and other areas.

5. Bacteria Resistance

A significant advantage of stainless steel is its ability to resist the growth of bacteria and microorganisms. The smooth, non-porous surface does not harbor bacteria, mold, or other pathogens, which is a key requirement in sterile environments. This resistance to microbial growth adds an extra layer of protection, reducing the risk of contamination when materials are transferred through the pass-through box.

6. Heat and Chemical Tolerance

In environments where items must be sterilized using heat, such as in autoclaves, or where aggressive cleaning chemicals are used, stainless steel's ability to tolerate high temperatures and harsh substances makes it an ideal material. It does not degrade under heat or exposure to strong cleaning agents, ensuring that the pass-through box remains effective over time. This chemical and thermal resilience supports long-term use in demanding environments without compromising safety or cleanliness.

7. Aesthetic and Professional Appearance

Stainless steel is not only functional but also offers a professional, clean appearance. Its sleek and polished surface conveys an image of hygiene and modernity, which is essential in industries like pharmaceuticals and biotechnology. The appearance of the pass-through box, in addition to its functionality, helps reinforce the perception of high standards and strict adherence to regulatory requirements in sterile environments.

Stainless steel is the material of choice for pass-through boxes in sterile environments for several compelling reasons. Its corrosion resistance, ease of cleaning, non-reactivity, durability, and resistance to bacteria make it ideally suited for use in highly controlled settings like pharmaceutical manufacturing and biotechnology laboratories. By ensuring that contamination is minimized and maintaining the integrity of cleanroom conditions, stainless steel pass-through boxes contribute to the safety and efficiency of critical processes. In addition, the material’s heat and chemical tolerance, combined with its professional appearance, make it a valuable asset in maintaining sterility and compliance in regulated industries.

English

English русский

русский Español

Español