In the construction of weighing booths to minimize electrostatic discharge (ESD), several materials and design considerations are typically employed:

Anti-static or Conductive Materials:

Anti-static plastics: Materials such as polypropylene (PP), polyethylene (PE), or acrylonitrile butadiene styrene (ABS) that have anti-static properties help dissipate static charges and minimize ESD risks.

Conductive metals: Stainless steel or aluminum alloys with conductive properties can be used for structural components or surfaces where ESD control is critical.

Static Dissipative Coatings and Finishes:

Surfaces may be coated or treated with static dissipative paints, epoxy resins, or laminates that enhance conductivity and reduce the buildup of static electricity.

These coatings prevent static charge accumulation and facilitate safe dissipation to ground, minimizing the risk of ESD events.

Grounding and Bonding Features:

Incorporation of grounding mechanisms such as conductive flooring, grounding straps, or metallic reinforcements in structural components ensures effective grounding of static charges.

Bonding all conductive elements together helps create a continuous path for static dissipation throughout the weighing booth.

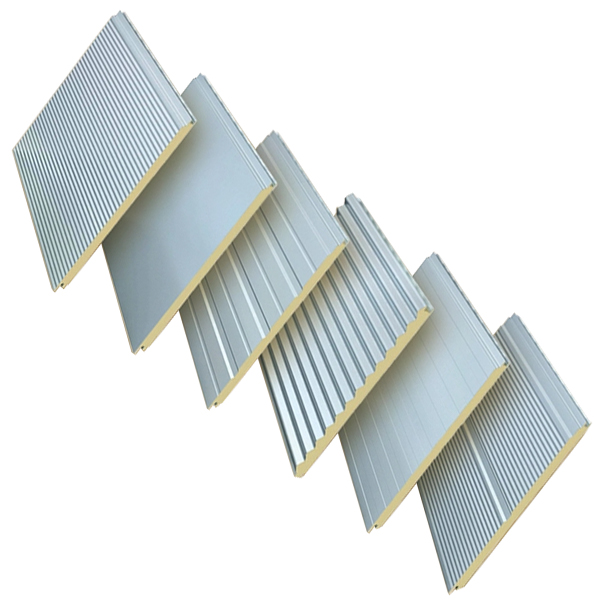

Insulating Materials for Isolation:

In areas where isolation from external static sources is needed, insulating materials such as high-density plastics or non-conductive ceramics may be used to prevent electrical contact and reduce ESD risks.

ESD Control Accessories:

Use of ESD control accessories like anti-static mats, wrist straps, and ionizers within the weighing booth environment further enhances ESD prevention measures.

These accessories help dissipate static charges from personnel and equipment interacting with sensitive weighing instruments.

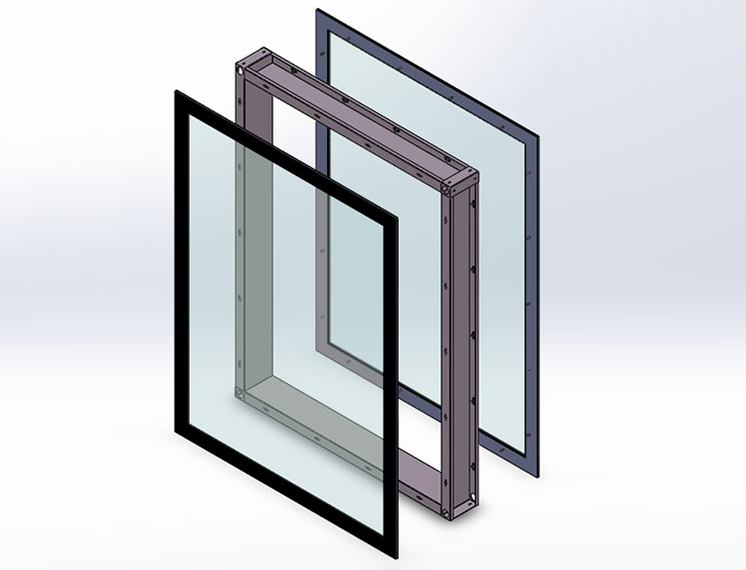

Sealing and Shielding Techniques:

Effective sealing of joints and openings in the booth structure prevents the ingress of airborne particulates and moisture, which can exacerbate ESD issues.

Shielding sensitive components within the booth from external electromagnetic interference (EMI) also contributes to overall ESD control.

By integrating these materials and design strategies, weighing booths can effectively mitigate the risks associated with electrostatic discharge, ensuring reliable performance and accuracy of weighing instruments in laboratory and industrial settings.

English

English русский

русский Español

Español