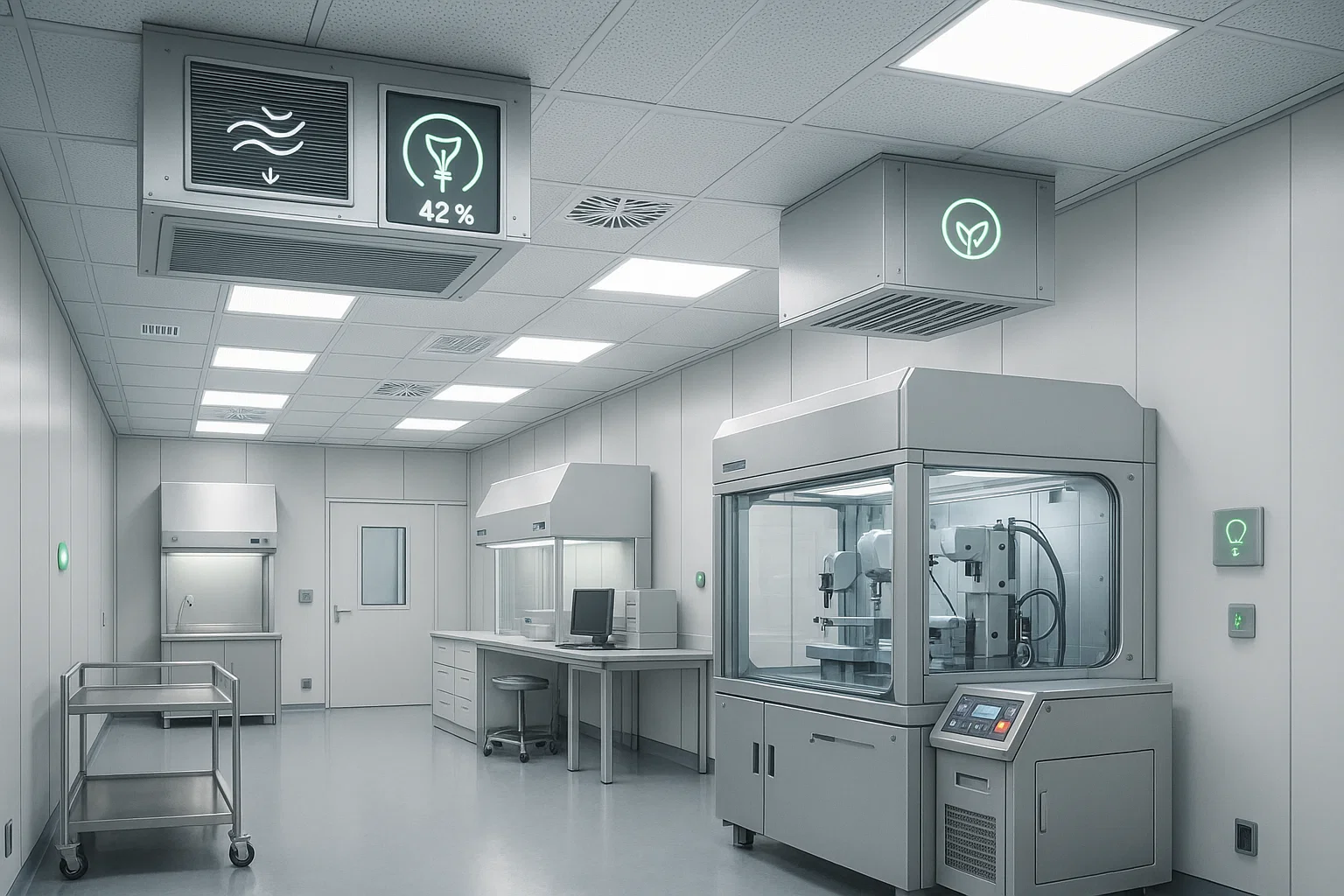

1. Airflow Management and Pressure Control:

Airflow Direction: Clean room doors are designed to maintain the desired airflow direction between different clean zones. Clean rooms often have a positive pressure relative to surrounding areas to ensure that air flows out, preventing contaminants from entering. Conversely, certain areas may operate under negative pressure to prevent contamination from escaping into the broader environment.

Door Seals and Pressure Differentials: The airtight seals around the door edges help preserve these pressure differences, ensuring that air does not escape or flow unintentionally between rooms with different cleanliness levels. By keeping the pressure differential intact, the door prevents the mixing of clean and less clean air.

2. Integration with HVAC Systems:

Air Handling Coordination: Clean room doors are typically integrated with the clean room’s HVAC system, which regulates airflow, temperature, and humidity. The air handling system ensures that filtered, clean air is consistently supplied to each clean zone, while doors help isolate areas with different airflow requirements.

Automated Control Systems: In more advanced setups, automated clean room doors may adjust based on real-time airflow or pressure readings. This ensures that each door opens and closes in a manner that maintains optimal airflow without disrupting the system's overall integrity.

3. Minimizing Cross-Contamination During Entry and Exit:

Air Curtains and Positive/Negative Pressure: Some clean room doors feature air curtains, which blow a controlled stream of air across the door opening to prevent airborne particles from moving between clean zones when the door is opened. Additionally, clean rooms may be designed with negative or positive pressure at entry points to help control the movement of air and minimize contamination during door operation.

Controlled Opening and Closing: The design of automatic or self-closing doors ensures that doors are only open for the minimum necessary time, reducing the exposure of clean zones to contamination from other areas. Automated systems can also help regulate the speed and timing of door openings, further enhancing airflow control.

4. Seamless Integration with Zoning Systems:

Clean Zones with Different Classifications: In facilities with multiple clean zones (e.g., ISO Class 5, Class 7, and Class 8 environments), doors are designed to limit the transfer of contaminants between these zones. For example, a door separating a higher-class (cleaner) zone from a lower-class (less clean) zone may incorporate additional sealing technologies or airflow control mechanisms to prevent contaminants from flowing into the higher-class zone.

Pressure Balancing: Clean room doors help balance the air pressure between zones by sealing effectively and maintaining the air exchange rates defined by the clean room’s specifications. This ensures that any air that passes through the door does so in a controlled manner, maintaining the integrity of each zone.

5. Minimizing Foot Traffic Impact:

Strategic Placement: In larger clean room setups, doors are often strategically placed to control foot traffic and minimize unnecessary movement between zones. This helps ensure that contamination risks are minimized during operational activities.

Restricted Access: Clean room doors may be fitted with access control mechanisms to ensure that only authorized personnel enter certain areas, further reducing the risk of cross-contamination. Doors that automatically close after entry or exit also reduce the chances of contaminants spreading between zones due to human movement.

6. Anticipating Contaminant Pathways:

Zoning with Airflow Studies: Clean room doors are often part of a carefully planned airflow study that determines the movement of clean air and the routes through which potential contaminants may travel. By ensuring that doors are positioned to control these pathways, the design helps prevent the movement of contaminants between zones.

Negative Pressure Design: In areas where contamination risk is high, doors may be part of a negative pressure system. This setup draws air into the room through the door rather than allowing air to escape, ensuring that contaminants stay within the controlled environment.

7. Maintaining Door Integrity:

Effective Door Materials: The materials used in clean room doors, such as stainless steel, aluminum, or special composite materials, are non-porous and resistant to the buildup of particles, which helps maintain airflow control and prevents particulate contamination through the door itself.

Seamless and Tight Fit: Clean room doors are designed with a tight fit to ensure that no gaps or cracks exist where air could pass through uncontrollably. This prevents the unintended mixing of air and ensures that air only moves as intended—whether to exhaust or supply filtered air.

English

English русский

русский Español

Español