Clean room windows play an important role in preventing the accumulation of static electricity in sensitive environments, where even a small static discharge could damage delicate electronic components or contaminate the environment. Here’s how clean room windows help in managing static electricity:

Use of Anti-Static Materials and Coatings: Many clean room windows are made from materials that are designed to be anti-static or are coated with anti-static films. These materials help dissipate any static charge that might build up on the window surface, reducing the risk of electrical discharges that could compromise the clean room’s environment.

Integration with the Grounding System: Clean room windows, especially those with metal frames, are often integrated into the room’s grounding system. Proper grounding of the window frames ensures that any static electricity that accumulates is safely conducted away from the window, preventing it from building up to dangerous levels.

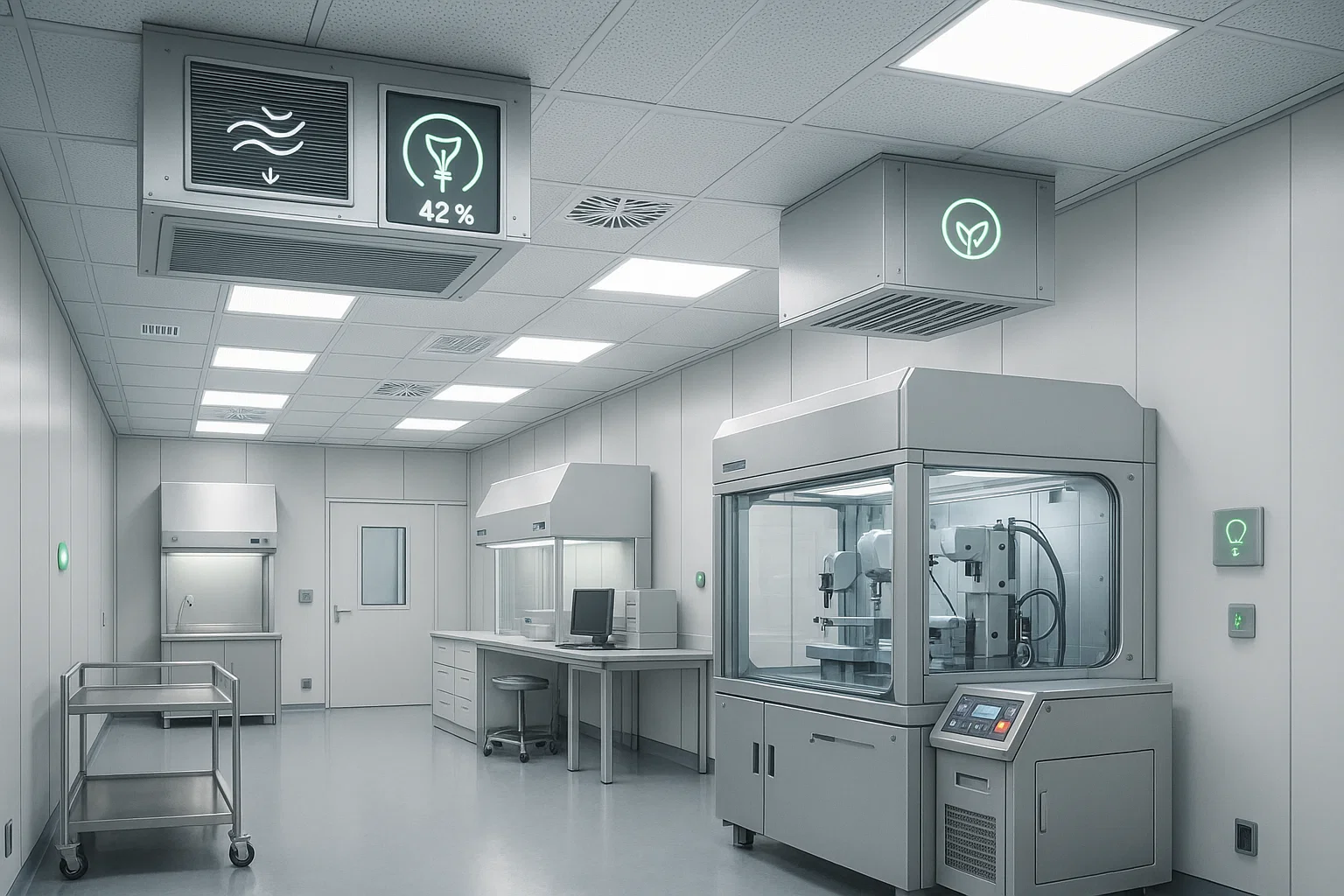

Control of Airflow Around Windows: The airflow in clean rooms is carefully controlled to minimize contamination, but it also plays a role in managing static electricity. Properly designed windows help maintain a stable, uniform airflow, reducing areas of turbulence that might contribute to static charge accumulation. Additionally, clean room windows often have specific designs to minimize the impact of airflow on static-sensitive equipment.

Use of Static Dissipative Materials: Some clean room windows are designed with static-dissipative materials that do not allow static charges to accumulate easily. These materials gradually dissipate static charges over time, maintaining a neutral charge on the window’s surface and reducing the likelihood of static buildup.

Prevention of Dust Accumulation: Static electricity can attract dust particles, which can settle on surfaces such as windows. Clean room windows are often made of smooth, non-porous materials that make it difficult for dust and other contaminants to accumulate. This is important because dust particles can carry static charge, and preventing their accumulation reduces the overall risk of static discharge.

Clearance and Sealing: Clean room windows are typically installed with tight seals and clearance from the surrounding environment to minimize the introduction of dust, moisture, or other factors that could contribute to static buildup. By preventing gaps or leaks around the window, the risk of static accumulation is further reduced.

Controlled Humidity: Many clean room windows are part of an HVAC system that controls the humidity levels within the room. Proper humidity control is one of the most effective ways to reduce the buildup of static electricity. Windows can be designed to ensure that the air surrounding them does not get too dry, which could otherwise lead to higher static charge accumulation.

Specialized Window Design for Sensitive Areas: In certain highly sensitive environments (such as those used in electronics manufacturing or pharmaceuticals), clean room windows may be specifically designed to prevent static electricity buildup. These windows may include additional conductive layers, anti-reflective coatings, or even built-in ionizers to ensure that no static charge accumulates and no discharge occurs.

In conclusion, clean room windows help prevent the accumulation of static electricity by using materials and coatings that dissipate static charges, integrating with the clean room’s grounding system, and ensuring that the environment around them is controlled (e.g., through airflow, humidity, and cleanliness). Their design and materials are essential in creating a static-free environment that is safe for sensitive processes and equipment.

English

English русский

русский Español

Español